Test bench for stator active steel 02.01.04 is intended to determine the condition of the stators in the repaired electric motors with the capacity up to 100 kW after winding removal. TestbBench selects cores with high losses before laying new winding and reduces unnecessary waste of the winding material.

Test bench for unimpregnated stators is intended for technological testing electric motor AC stators having capacity up to 100 kW before winding impregnation.

Test bench is intended for carrying out acceptance trials of the overhauled synchronous generators and electric machines of direct current with the capacity up to 100 kW.

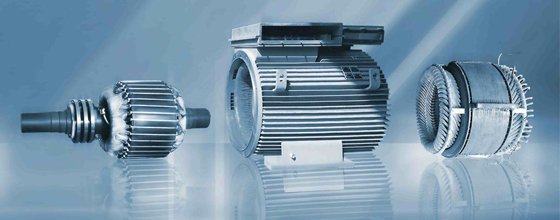

Testing bench for asynchronous electric motors with the capacity up to 100 kW is intended to test asynchronous AC electrical motors with 50 Hz frequency and 220, 380, 500 and 600 V voltage for short-circuited and phase rotors with up to 100 kW after overhaul.

Testing bench for asynchronous electric motors with the capacity up to 100 kW is intended to automatic test asynchronous AC electrical motors with 50 Hz frequency and 220, 380, 500 and 600 V voltage for short-circuited and phase rotors with up to 100 kW after overhaul.

no picture

Test bench is intended for commissioning trials of welding generators with arch welding by direct current with the capacity of up to 25 kW according to GOST 304-82 standard.

Layer's table is intended for laying annular winding of electric motors up to 100 kW while repairing.

no picture

UPGV-5 is intended for absorption from the fulfilled gases of various harmful components: : SO, NOx, SO2, H2S, dust, soot.

Suspended device for stator mounting is used for turning stator up to the 7th overall dimensions by means of hoisting device used for packing windings. It is suspended at the hoisting device. Stators of wide range in length and weight are securely suspended owing to an adjusted suspension point.

Device to take rotor out is used to take rotor in and out of stator with the help of a hoisting mechanism. The adjustment point of a hoisting mechanism guarantees secures rotor fixation exactly along the horizontal plane.

Briquetting press is intended for briquetting the remains of the winding wire. The press provides briquetting of round and rectangular waste wire with the cross section of up to 16 mm2.

Machine to remove bearings is intended for removing bearings from electric motor rotors of 3…9 overall dimensions.

Cutting machine is intended to cut the frontal parts of the stator winding in electrical motors. Stator is fixed by using a three-cam chuck, which provides precise centering. The chuck features automatic support of the clamping force. Cutting of front parts can be performed in manual or semiautomatic mode.

Drying installation is intended for convection drying of large size parts with mechanized loading in automatic drying mode.

Warehouse-Pallet-Conveyor is intended for storing rotors, caps, motor shields etc. in baskets, the capacity is up to 100kW.

Winding machine is intended for winding of section group (coils) of annular winding of electric motors with capacity from 0.12 up to 100 kW

Relevelling machine is intended for rolling the traces (relevelling) of the curve on the bars of isolating materials for notch (slot) boxes of electric motor stator.

Machine to produce notch (slot) wedges is intended for fabricating wooden slot wedges using milling.

Saturation plant is intended for impregnating electric motor stators by means of electroisolating varnishes.

Hydro bench is intended for trials checking mechanical strength and scaling of the coatings for explosion proof electric motors using a hydraulic method.

Washing machine is intended to wash bearings and small parts in the heated washing solution.

Annealing installation is intended to anneal winding isolation while repairing electric motor stator.

Multipurpose furnace is intended to anneal winding before stator dismantling and their drying after impregnation.

Ventilating ejector is used in ventilation systems with big dirt level in moved air.

Machine to remove windings is intended for removing annular windings from electric motor stator after annealing.

Multipurpose machine is intended for removing bearings and a set of contact rings from electric motor rotors and pulling annular windings out of electric motor stators with the height of the centers up to 315 mm.

Blowing chamber is intended for blowing around the stator with pressed air at the stage of their preparation for winding laying.

Induction heater is intended for heating bearings, bushings, rings, etc. before fixing them to rotor shafts and electric motor armatures. - it provides quick and smooth heating process - it possesses replaceable core

Induction heater is intended for heating bearings, bushings, rings, etc. before fixing them to rotor shafts and electric motor armatures. - it provides quick and smooth heating process - it possesses replaceable core

Dismantling test bench is intended for removing bearing shields and bearings from rotor shaft.

Annealing furnace is intended to anneal windings of electric motor without air access. The parts are loaded into the furnace by means of a truck loader. Annealing process is done automatically.

Stator manipulator is intended for mechanical turning of stators of the 7th …9th overall dimension while packing windings during electric motor repair. The device provides a turning angle from 0o to 360o and stator fixation in the given position.

Impregnating tank is intended for impregnating electrical equipment in electroisolating varnishes.

Manual lever scissors are intended for cutting sheet isolation materials used while repairing electric motors.

Assembly bench is intended for 7… 13 dimensions electric motor assembly using the method of installing stator on the console-fixed rotor.

The rack is intended for coils installation and pulling wires for account of drum braking in the time of coil-processing of windings.

Dyeing chamber is intended for dyeing parts having mass up to 1000 kg by means of spraying. The chamber is provided with hydrofilter.

no picture

Universal furnace with the front loading is intended for annealing electric motor windings without air access and their drying after impregnation. The parts are loaded into the furnace by means of a truck loader. Annealing / drying process is done automatically.

Vacuum impregnation installation is intended for impregnation electric motor stators with preliminary discharging in the impregnation tank. Cycle duration is programmed by a control unit. Impregnation process is completely automatized.

Русский

Русский