Welcome to SPV “Electromash” Ltd

SPV “Electromash” Ltd was based in 1997.

Company profile is designing, working out and manufacturing of the equipment for repair:

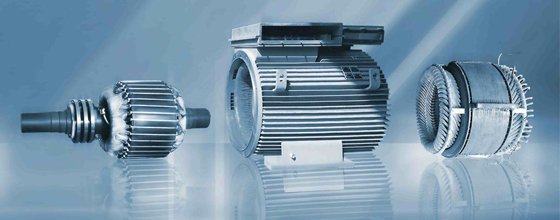

— D. C. and A. C. electric motors and generators

— Measuring and power transformers,

— Other electric equipment (electromagnets, etc.)

We develop and manufacture unique benches and test machines for electric motors and transformers

SPV “Electromash” Ltd carries out next tasks:

— Designing of electrical repair shop under customer’s technical project;

— Manufacturing of the unique equipment for repair of electric motors and transformers;

— Manufacturing of test benches and stations for electric motors and transformers;

— Installation supervision and testing and commissioning of equipment for repair of electric motors and transformers and test benches;

— Training of employees of electric repair shop;

— Servicing and warranty maintenance of the equipment for electrical repair shop;

— Free service updating of the software for testing benches and machines;

One of the directions of SPV “Electromash” Ltd is working out of technology of a detonation spraying of materials with different properties. Increasingly demand for new technology is explained that the detonation spraying is the most effective way of increase of resource of work of details of vehicles and machinery working in the conditions of high load, heavy wear, high temperature exploration and exposure to the aggressive environments.

We developed and patented the technology of overhaul of wheels of work electrical submersible pumping system for oil recovery. Today this technology has no analogues in the world.

Collective of SPV “Electromash” Ltd constantly works over perfection of the equipment and develops new ideas for satisfaction of requirements of the customer.

Русский

Русский