The machine is intended for rewinding the tape from factory made bobbins into the coils of smaller diameter.

The installation is intended to solder copper bus by using hard solders in the process of electric machine repair. - 3 position switch to commutate operating current - mechanical clamp of the electrode - fixation of the soldered bus.

no picture

The machine is intended for tightening bushing isolation of the slot section in electric machine winding by the means of rolling.

The transformer is intended for soldering a copper bus bar by means of brazers and for welding copper wires of circular cross-section. -4 position electric current circuit breaker -tongs for soldering with a braze.

The station is intended to test power transformers with capacity up to 5000 kVA with voltage up to 10 kV.

The station is intended to test power transformers of the I-IV dimensions with voltage up to 10 kV acoording to demands of GOST-3484.1, GOST-22756, GOST-21023, GOST-3484.3.

no picture

The bench is intended to test welding transformers used for manual arch welding with 220 and 380 V and up to 20 kW capacity.

The machine is intended for cutting out segments and stripes made from electrocardboard while producing isolation parts for power transformers.

The machine is intended for cutting out rings and stripes made from electrocardboard while producing isolation parts for power transformers.

The machine is intended for corrugation of electro cardboard used in the process of transformer coil winding (corrugators form the canals for transformer oil circulation).

Extensible winding pattern is intended to wind windings of the transformers with III-IV dimensions on isolation cylinders.

The machine is intended for corrugation of electro-cardboard used for isolation of power transformer windings.

The device is intended for pulling wires while winding transformer windings and clamping them in the period of winding machine stoppage halt.

The machine is intended for milling radial surfaces of the glued rings isolation of transformers.

The machine is intended for making electrocardboard stripes dense before producing power transformer isolation.

The installation is intended for convection drying of large size parts with mechanized loading and automatic control of the drying mode.

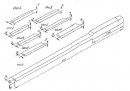

Machine is intended for row winding the coils on rigid square and round frames. Machine design permits to wind coils simultaneously on three frames. Machine possesses winding step adjustment mechanism and automatic spindle stops after a definite number of winding loops had been obtained.

The machine is intended to wind coils of transformers made of conductors with circular and rectangular cross sections using cylinders made of cardboard. The machine is equipped with a tail stock.

The installation is intended for absorption drying and cleaning transformer oil from mechanical impurities in oil filled electrical apparatus. The installation can be used for transformer oil regeneration provided synthetic tseolit is replaced by silicogel or other sorbent produced for this purpose.

Scissors are intended for cutting sheet isolation materials used while repairing electric motors.

The machine is intended to wind electric motor and transformer coils having circular and rectangular conductor cross-sections.

no picture

The machine is intended for fabricating electro cardboard parts of rectangular isolation for I-IV dimension transformers.

The bath is intended for tinning of copper wire, tyre and tips of cables of electrotechnical products. It is applied in the time of repair and manufacturing of windings of electric equipment.

The chamber is intended for dyeing large size parts by means of spraying.

Unit for measuring Active Resistance of electric machine windings (КИСО) is intended for measuring winding active resistance and revealing faults in three phase transformers.

no picture

The device is intended for cutting out gaskets out of paronite material and cardboard.

The machine is intended to cover parts made from electrocardboard with varnish.

The installation is intended to solder copper bus by using hard solders in the process of electric machine repair. - 3 position switch to commutate operating current - mechanical clamp of the electrode - fixation of the soldered bus.

Installation to clean and restore the wire is intended for restoration and cleaning of winding wires from old isolation left after annealing.

The installation is intended for putting glasstape isolation on copper wires of annular section with diameter from 1,6 to 4,1 mm and rectangular section with dimensions from 1x3mm to 3x90 mm, with simultaneous laying, impregnation and drying.

The installation is intended to isolate winding wires by means of tape isolating materials.

no picture

Annealing furnace is intended for copper wire annealing for recurring application. Annealing is performed without oxygen access. Annealing chamber is isolated from environment by water gate.

no picture

Machine to cut isolation paper is intended for cutting coils made of electrotechnical paper of 500-750 mm width into rolls of 20-150 mm width.

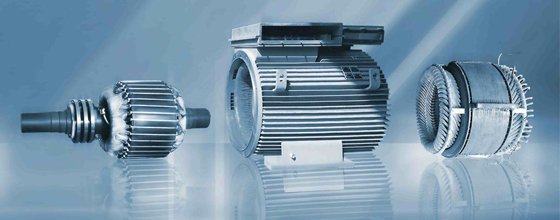

Test bench for stator active steel 02.01.04 is intended to determine the condition of the stators in the repaired electric motors with the capacity up to 100 kW after winding removal. TestbBench selects cores with high losses before laying new winding and reduces unnecessary waste of the winding material.

Test bench for unimpregnated stators is intended for technological testing electric motor AC stators having capacity up to 100 kW before winding impregnation.

Test bench is intended for carrying out acceptance trials of the overhauled synchronous generators and electric machines of direct current with the capacity up to 100 kW.

Testing bench for asynchronous electric motors with the capacity up to 100 kW is intended to test asynchronous AC electrical motors with 50 Hz frequency and 220, 380, 500 and 600 V voltage for short-circuited and phase rotors with up to 100 kW after overhaul.

Testing bench for asynchronous electric motors with the capacity up to 100 kW is intended to automatic test asynchronous AC electrical motors with 50 Hz frequency and 220, 380, 500 and 600 V voltage for short-circuited and phase rotors with up to 100 kW after overhaul.

Hydro bench is intended for trials checking mechanical strength and scaling of the coatings for explosion proof electric motors using a hydraulic method.

The station is intended to test power transformers with capacity up to 5000 kVA with voltage up to 10 kV.

The station is intended to test power transformers of the I-IV dimensions with voltage up to 10 kV acoording to demands of GOST-3484.1, GOST-22756, GOST-21023, GOST-3484.3.

no picture

The bench is intended to test welding transformers used for manual arch welding with 220 and 380 V and up to 20 kW capacity.

The behch is intended to reveal faults in stators of repaired electric motors with the capacity from 100 to 1000 kW after winding removal. The bench reveals cores with high losses before packing new winding and reduces winding wire extra waste.

Test station is intended to test AC asynchronous and synchronous electric motors after overhaul. Voltage of tested electric motor, kV: from 0.66 up to 6. Capacity of tested electric motor, kW: 100-400 250-1000. Equipment installed at the station provides the following trials: - measuring winding isolation resistance in relation to the machine body and between the winding. - Measuring resistance of windings under direct current in practically cold state. - Trials under increased frequency of rotation. - Electric stability testing of winding isolation in relation to machine body and between the windings. - Electric stability testing of winding interloop isolation. - determination of idle running current and losses; - determination of short circuit voltage and losses; - Determination of transformation ratio (for machines with phase rotor). - Idle running. - Determination of idle current for synchronous machines.

no picture

Test station is intended to test asynchronous and synchronous machines with the capacity from 100 up to 1000 kW with up to 6 kW voltage, and from 100 up to 400 kW with 0,66 kV voltage, transformers with capacity up to 2000 kVA with up to 10 kV voltage. Test station provides electric machine trials according to demands of the following technical standards: GOST 7217-87, GOST 183-74, GOST 10169-77, GOST 11828-86, GOST 3484-88, GOST 11677-85. Station equipment allows to perform the following trials: For electric motors: - measuring resistance of winding isolation in relation to body and between the phases; - measuring winding resistance offered to direct current in practically cold state; - testing winding isolation in relation to body and between the windings to prove electric stability; - idle running of electrical machine; - determination of idle current and losses; - determination of short circuit voltage and losses; - determination of transformation ratio (for electrical motors with phase rotor); - testing under increased frequency of rotation (for asynchronous machines with phase rotor and synchronous machines if rotation windings or bandages were under repair). - Electrical stability testing winding interloop isolation; - Idle running for synchronous machines. For transformers: - measuring resistance of winding isolation and absorption ratio; - determination of transformation ratio; - check up a set of winding connections; - testing electric stability of winding isolation by applying increased voltage of industrial frequency; - determination of idle current and losses; - determination of short circuit voltage and losses; - measuring winding resistance offered to direct current in practically cold state;

The Test Bench is intended for commissioning trials of welding generators with arch welding by direct current with the capacity of up to 25 kW according to GOST 304-82 standard.

A Unit for measuring active resistance of electric machine windings (KISO) is intended for measuring winding active resistance and revealing faults in three phase transformers.

Washing chamber is intended for degreasing and washing mechanical parts loaded into the basket using the heated washing solution and compressed air barbotage.

The device is a part of the installation set intended for trials and parameters of the tested units recording. It perform the following recording and indication (display) of: - Current meaning of oil temperature; - Current meaning of oil pressure; - Current meaning of vibroshaft rotations; - Current meaning of temperature in bearing units; - Sound alarm at overheating bearing units and oil over admitted temperature limit; - Software link to provide monitoring and logging of measured parameters.

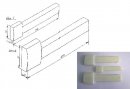

Drawing to lay annular windings for 100 kW electric motors.

Iron to lay annular windings of up to 100 kW electric motors.

Русский

Русский